Crystolite

Microfiltration Media & SDI

Introduction

As a global leader in absorbents technology and iron and manganese removal filtration, Watch-Water® has developed a unique industrial water and wastewater treatment filtration solution.

For microfiltration, Crystolite™ filtration media (CFM) is very robust, long life, back washable filter media. Crystolite™ filtration media meets the needs of all industrial, municipal, residential and water reuse for any application. This unique, high-capacity media is designed to reduce the waste of expensive cartridges and plastic filter housings. This Crystolite™ filtration media is an excellent alternative to all microfiltration membranes.

Watch-Water® GmbH has debuted its all new CRYSTOLITE water filtration media. Utilizing the microfiltration it provides an exceptional level of clearness and harmful trace metals removal. Watch-Water® marks the first time that a Microfiltration based filter media has been commercially developed for Water Filtration within the Industry.

Best Features

• Removes Solids and SDI

• Compact

• High filtration rates

• Resistance to heavy metals

• Continuous operation and performance

• Easy operation, maintenance & control

• Lifespan is 10-15 years

• pH environments from 3 to 12

• High temperatures up to 80°C

Application

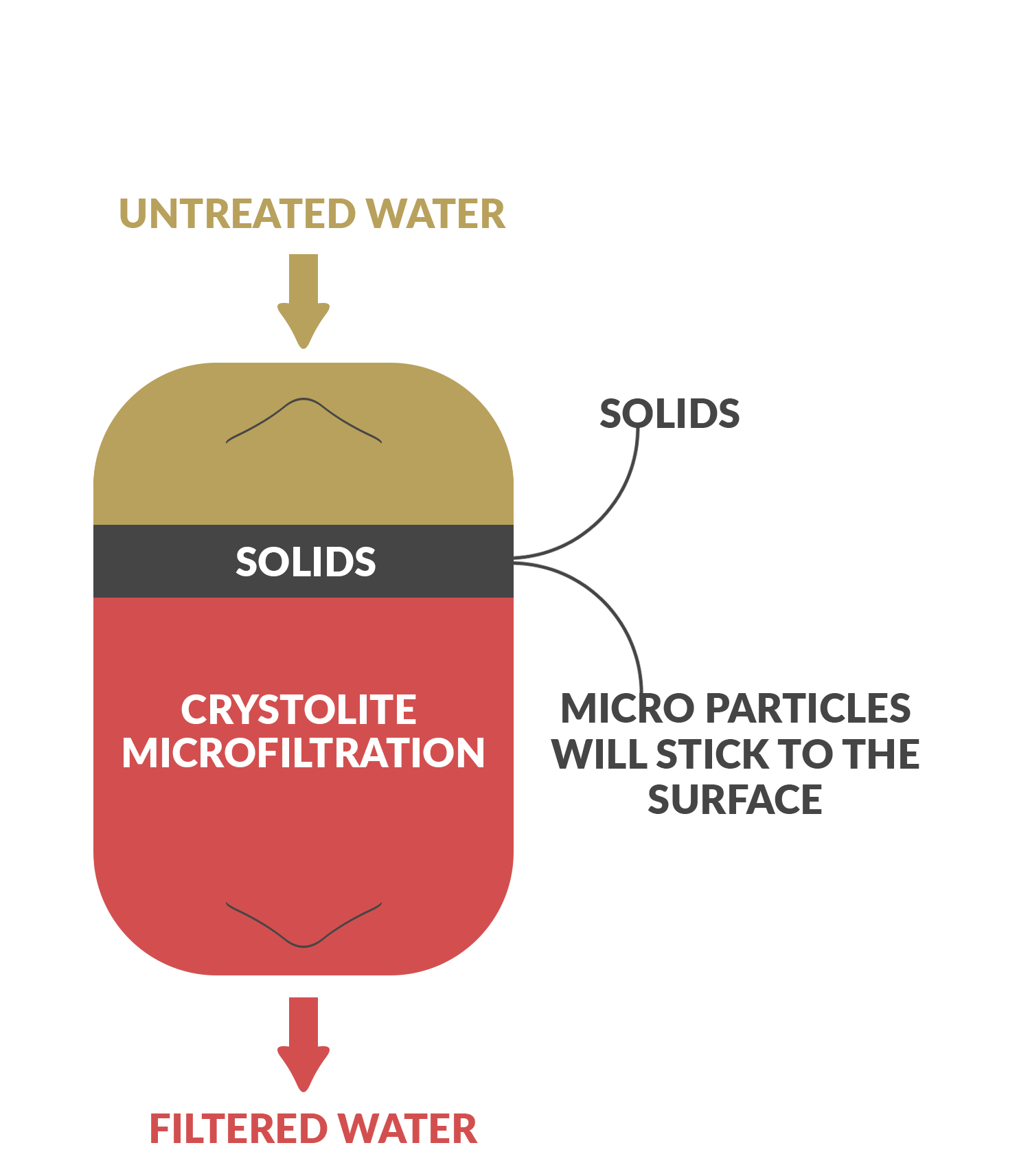

CRYSTOLITE – Microfiltration Media has been developed over several years of careful and extensive real world field-testing to ensure an unrivaled degree of harmful solids and heavy metals removal from water systems. It reduces conductivity levels that’s caused by micro-solids. What’s more is, CRYSTOLITE – Microfiltration Media can provide water filtration 5 – 8 times greater reduction of harmful-solids & SDI reduction than its closest competitors. Using CrystoliteTM media in a pressure vessel to provide a microfiltration effect, the CrystoliteTM media allows the water to flow through the top distributor on the top of media layer, when suspended solids are held on the highest surface area of the media allows only clean water to flow through the CrystoliteTM media. As a result, CrystoliteTM can be used to filter down 0.5 microns without clogging. It allows all suspended solids to accumulate on the surface of the CrystoliteTM media and are easily backwashed to drain. The system can be designed either manual backwash or by using automatic backwash cycle, the backwash cycle is maximum 10 minutes which uses 80% less water then any traditional anthracite or multimedia filters, it is because 90% of the solids are captured on surface and not inside of the CrystoliteTM media-bed. This results if the High-tech filtration that can filter solids and particles down to submicron levels at 10 to 15 times the flow rate of all traditional filters. Backwash water reduction is up to 80%.

Applications

- Ammonia removal

- Trace heavy metal removal

- Pretreatment of RO & RO reclaim

- Power stations

- Steel and iron mils

- Zero blown down

- High solids wastewater

-

Zero blown down

- o Cooling towers

- o Boiler water

- Swimming pools

-

Circulation plants for

- o Plating processes

- o Printed circuits